Hot Plates & Hot Plate/Stirrers

The ultimate selection guide to hotplates and magnetic stirrers

Plate Material

Different hotplates and stirring hotplates come with various plate materials. The choice largely depends on the specific needs of your application and the characteristics you seek from the plate. The material of the plate plays a significant role in determining its temperature range and evenness.

Ceramic plates can reach remarkably high temperatures with outstanding chemical resistance, their temperature consistency isn't always uniform due to cooler edges. It's also essential to avoid using them with reflective vessels or sandbaths.

...continue reading below the images

-

-

-

- Manufacturers: Ohaus®

- Brand: Guardian 3000

- SECO Part No: OHS-30680267

- Manufacturer Part No: 30680267

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Guardian 3000 30680267

Affordable Digital Hotplate Stirrers Designed More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

Cimarec+™ Stirring Hotplate

Stirring Hotplate, 10 L x 5 W x 3.6" H, Ceramic Top Plate, LED Display, US-style Plug, 10.8 x 10.8 cm Surface Area Heating, 50 to 1,500 rpm Speed, 540°C Maximum Temperature, 100 to 120 V, 50/60 Hz

-

-

-

-

- Manufacturers: Thermo Fisher Scientific

- Brand: Thermo Fisher Scientific

- SECO Part No: 18-6825-01

- Sold As: Each

- Manufacturer Part No: HP11515B

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Thermo Fisher Scientific HP11515B

Hotplate, Cast Aluminum, 6.13 x 6.13" Heating More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

Cimarec+™ Ceramic Stirrer

Stirrer, 10 L x 5 W x 3.6" H, Ceramic, 50 to 1500 rpm Speed, 100 to 120 V, 50/60 Hz, 5 w, 50 to 1,500 rpm Stirring Range, USA Plug Style, 4.25 x 4.25" Top Plate Surface Area, Includes 1 Power Cord, Flexible, Robust Design

-

-

-

-

- Manufacturers: Dynalon® Labware

- Brand: Dynalon® Labware

- SECO Part No: DYN-304435-0010

- Sold As: 12/Case

- Manufacturer Part No: 304435-0010

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Dynalon® Labware 304435-0010

Micro Stirring Bar, 3 OD x 10 mm L, Red, PTFE More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Thermo Fisher Scientific

- Brand: SuperNuova™

- SECO Part No: 22-2560-12

- Sold As: Each

- Manufacturer Part No: SP88857190

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

SuperNuova™ SP88857190

Stirring Hotplate, 13 L x 8.2 W x 3.8" H, Cer More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Ohaus®

- Brand: Ohaus®

- SECO Part No: OHS-30400146

- Manufacturer Part No: 30400146

- UPC: 030955720807

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Ohaus® 30400146

Support Rod and Clamp Kit

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

Spinbar® PTFE Coated Circulus™ Magnetic ...

Magnetic Stirring Bar, 35 mm L, 8 mm Bar dia, 20 mm End Disk dia, White, Circulus™ Shape, PTFE Coated Alnico Magnet, Autoclavable, Without Pivot Ring, Ideal For Containers With Round or Convex Bottoms

-

-

-

-

- Manufacturers: Thermo Fisher Scientific

- Brand: Thermo Fisher Scientific

- SECO Part No: 18-6490-03

- Sold As: Each

- Manufacturer Part No: 88880002

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Thermo Fisher Scientific 88880002

RT2 Hotplate, 25 kg, 11.42 L x 6.34 W x 3.94" More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

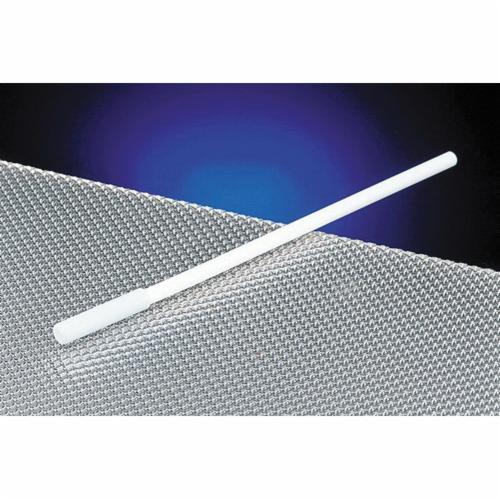

Dynalon® Labware Polypropylene Stirring Bar Re...

Stirring Bar Retriever, 304 mm L, Polypropylene, For Use with All Stirring Bars, Entire Stir Bar Retriever is Totally Encased in Chemically Resistant Polypropylene

-

-

-

-

Cimarec+™ Ceramic Hotplate with 1 Power Cord

Hotplate, 10 L x 5 W x 3.6" H, Ceramic, 4.25 x 4.25" Heating Area, 100 to 120 V, 50/60 Hz, 540°C Temperature Range, US-style Plug Type, 5.7 lb Weight, Easy-to-read LED Display for Heating, With Power Cord

-

-

-

-

- Manufacturers: Ohaus®

- Brand: Ohaus®

- SECO Part No: OHS-30541637

- Manufacturer Part No: 30541637

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Ohaus® 30541637

Our signature SafetyHeat™ and SmartHeat More...

-

Login to View Your Price

List Price :

-

Add to cart

-

Aluminium plates stand out for their durability, especially against accidental bumps in the lab setting. Their major advantage is the consistent temperature across the plate thanks to their all-over heating feature. However, some aspects to consider include:

Ceramic-coated aluminium plates bridge the benefits of both materials. They guarantee even temperature distribution and a commendable chemical resistance due to their ceramic layer. Nevertheless, since the core is aluminium-based, they don't attain the elevated temperatures that pure ceramic plates can achieve.

Safety Considerations

When dealing with stirring tasks, ensuring safety is paramount, and this is accentuated when a hotplate stirrer is in use. Some of the safety aspects to consider include:

- Gradual speed increase: This function lets you gently escalate the stirring speed, reducing the risk of splatters.

- Heat alert system: An illuminating indicator comes on when the hotplate stirrer reaches temperatures typically beyond 50°C.

- Stirring safeguard: In situations where the stirrer motor halts or malfunctions, the heating component is designed to switch off automatically.

- Probe security: If a probe detaches from the sample, the safety mechanism ensures the heater turns off.

- Overcurrent protection: This feature helps in guarding against abnormally high currents, reducing the danger of fires.

- Temperature control: This is particularly beneficial for samples susceptible to specific temperatures, allowing you to set the highest temperature the hotplate can attain.

- Protective barrier: Some hotplate stirrers can be accessorized with shields that offer protection from potential spills, splashes, and airborne particles.

Magnetic Stir Bars

Also known as "flea" or "spinner", are a crucial accessory in many laboratories. The right stir bar can greatly influence the efficiency of mixing and the outcome of a reaction.

Size and Shape:

- Length: The stir bar's length should be about one-third the diameter of the container's base. A stir bar that's too long may not spin properly, and one that's too short may not provide effective mixing.

- Shape: There are various shapes available - cylindrical, oval, cross-shaped, and more. The choice often depends on the nature of the liquid and the container. For instance, cross-shaped stir bars are good for viscous liquids, while oval ones are suitable for round-bottomed flasks.

Material:

- PTFE-coated: Most stir bars are PTFE-coated (polytetrafluoroethylene, a type of Teflon) making them chemically inert, easy to clean, and resistant to high temperatures.

Magnetic Core:

- The strength of the magnet inside the stir bar determines its coupling with the magnetic stirrer. A strong magnet ensures the stir bar doesn't decouple and stop stirring, especially at high speeds.

End Type:

- Pivot ring: Stir bars with a pivot ring in the middle reduce friction, which is beneficial when stirring viscous solutions or using large stir bars.

- Plain: Suitable for most regular stirring applications in flat-bottomed containers.

Container Shape:

- If using a round-bottomed flask, a stir bar that's slightly curved or with a pivot ring might be more appropriate to ensure it remains centered.

Viscosity of Liquid:

- For more viscous liquids, consider stir bars with larger diameters or specialized designs (like cross-shaped) to ensure effective mixing.

Sterility:

- For biological applications, it might be crucial to ensure that the stir bar can be autoclaved or sterilized without damaging its magnetic properties.

Retrieval:

- Consider using a stir bar retriever, a separate accessory, for removing the stir bar from containers, especially if working with hazardous materials.

Choose SECO: where service meets value

Volume pricing: At SECO, we understand the needs of large-scale operations and budget constraints. That's why we offer volume pricing, ensuring that when you buy more, you save more. It's our way of supporting labs and industries in scaling their operations without breaking the bank.

Low shipping cost: Your order comes directly out of our warehouse in the NE, that is how we can ensure that you benefit from competitively low shipping rates.

Reliable delivery: Our commitment to you goes beyond quality products. SECO ensures that your supplies reach you on time, every time. With a proven track record, you can count on us for timely deliveries that keep your operations running smoothly.

No time for browsing around?

Have a question? Need assistance? Reach out to us. Our knowledgeable customer service team is always ready to assist you. We can help you find the right products to suit your needs, answer any questions you might have, and even place your order for you.